Aluminium scrap polishing sieving separator

Aluminium scrap polishing sieving separator

- Description

- Inquiry

Description

Aluminium scrap polishing sieving separator

Aluminium scrap polishing sieving separator

Aluminium scrap polishing sieving separator description

Aluminum scrap polishing sieving separating is one important procedure in aluminum recycling industry, which is an important guarantee for the increasing aluminum recovery rate.

To reduce the selection and separation cost of aluminum scrap before melting, which plays a decisive role in the secondary aluminum manufacturers.

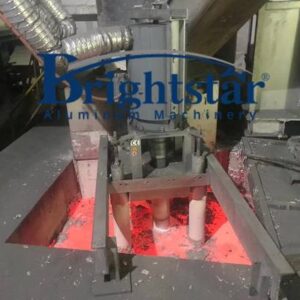

The aluminum scrap polishing sieving separator function can be achieved by the rotation of the drum.

Aluminum scrap will be collided in the drum that can remove the most dust and oxidized layer of surface and impurity, then sieve in different grades to get the mechanical operation, at the same time, automatic sorting in different sizes of the material, so that can reduce the labor intensity greatly, which is convenient for the resorting and remelting intensively.

Main models: BS1520 BS1320 BS1100

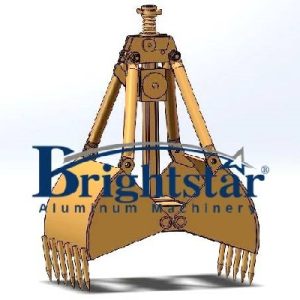

Equipment main parts

Bottom parts, bracket

Frequency control motor and transmission mechanism

Feeding frame equipped with vibration motor

Machine body rotary drum φ1320mm

Environmental protection vacuum fan(One set) Customer-supplied environmental protection dust removal system and joint flue pipe

Electronic control system

Aluminium scrap polishing sieving separator, the most effective way for aluminium scrap polishing and sorting.