Aluminum chips briquetting machine

Aluminum chips briquetting machine

- அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ்

- அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ்

அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ்

Aluminum chips briquetting machine

Aluminum chips briquetting machine

What is aluminum chips briquetting machine

An aluminum chips briquetting machine is a piece of equipment used to compress aluminum chips or shavings into dense, cylindrical briquettes.

These briquettes are then suitable for recycling or melting down in foundries for further processing.

It compresses loose aluminum chips, சவரன், and other scrap materials into dense blocks called briquettes.

This is achieved by applying high hydraulic pressure to the aluminum chips forcing out air and coolant and compacting the metal.

What are the types of aluminum chips briquetting machine?

There are two main types of aluminum chip briquetting machines:

Horizontal Briquetting Machine:

This design is commonly used for high-volume aluminum chip processing.

The machine loads aluminum chips horizontally into a chamber.

A hydraulic ram then compresses the chips into a dense briquette form as it moves through the chamber.

Horizontal briquetting machines are known for their:

High production capacity

Ability to handle large volumes of chips

Suitability for continuous operation

| அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் | Diameter of briquette | Weight of briquette | Shift production |

| BS16-37-180 | Φ110mm | 1.7-2.1kgs | 4-5அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

| BS15-67-323 | Φ180mm | 5.7-7kgs | 12-16அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

Vertical Briquetting Machine:

This type of machine is ideal for applications with lower production volumes or limited floor space.

Aluminum chips are loaded vertically into a hopper at the top of the machine.

A hydraulic ram applies pressure from the top, forcing the chips down into a mold that shapes them into briquettes.

Vertical briquetting machines offer advantages such as:

Smaller footprint

Lower initial investment cost

Easier loading and unloading of chips

The best type of aluminum chip briquetting machine for your operation will depend on your specific needs, such as production volume, chip size, and available space.

|

அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

Briquette dia |

Briquette weight |

Shift production |

| Y83AL-2500 | Φ100mm | 1.6kgs | 2~3T |

| Y83AL-3150 | Φ120mm | 2.3kgs | 3~4T |

| Y83AL-3600 | Φ130mm | 2.7kgs | 3.5~5T |

| Y83AL-5000 | Φ145/Φ200 square | 5.3kgs | 8அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

| Y83AL-6300 | Φ160/Φ200 square | 11.5kgs | 15~20T |

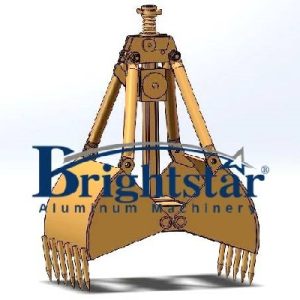

What are the main parts of aluminum chips briquetting machine?

An aluminum chip briquetting machine is comprised of several key parts that work together to compress loose aluminum chips into dense briquettes.

Here’s a breakdown of the main components:

1. Main Frame:

This is the robust body of the machine, typically constructed from welded steel beams and columns.

It provides a stable platform for all other components and needs to withstand the significant forces involved in the compression process.

2. Hydraulic System:

The heart of the machine, the hydraulic system generates the high pressure required for compressing the aluminum chips.

It consists of a hydraulic pump, மோட்டார், valves, piping, and a reservoir for the hydraulic fluid.

The pump draws fluid from the reservoir and pressurizes it. The valves control the direction and flow of the pressurized fluid to the hydraulic cylinders.

3. Hydraulic Cylinders:

These are powerful actuators that convert the hydraulic pressure into mechanical force.

There are typically two main cylinders in a briquetting machine:

Main Pressing Cylinder: This is the primary cylinder responsible for applying the compressive force to the aluminum chips in the mold.

Material-Pushing Cylinder (Optional): This secondary cylinder (not present in all machines) helps push the compressed briquette out of the mold cavity.

4. Mold and Mold Frame:

The mold is the heart of the briquette-forming process. It’s a high-strength steel cavity that determines the final shape and density of the briquettes.

The mold frame holds the mold in place and ensures proper alignment with the pressing cylinder.

5. Control System

Modern briquetting machines often incorporate a PLC (Programmable Logic Controller) based control system.

This system automates the operation of the machine, controlling the sequence of cylinder movements, pressure levels, and safety features.

6. Hopper (Optional):

This is a feeding chamber located at the top of some vertical briquetting machines.

Aluminum chips are loaded into the hopper and then gravity-fed into the mold cavity.

Additional Parts:

Depending on the specific machine design, there might be additional components like safety interlocks, limit switches, pressure gauges, and cooling systems for the hydraulic fluid.

Features of aluminum chips briquetting machine

Hydraulic System: Most aluminum chips briquetting machines utilize a hydraulic system to compress the aluminum chips into briquettes. This hydraulic system applies pressure to compact the chips, ensuring high density and uniform shape of the briquettes.

Compact Design: Aluminum chips briquetting machines are designed to be compact and efficient, allowing for easy installation and operation in various industrial settings. They often have a small footprint to save space on the factory floor.

Durable Construction: High-quality wear-resistant materials are used to handle the tough task of compressing metal. This translates to a long lifespan for the machine.

Automatic Operation: Many modern aluminum chips briquetting machines feature automatic operation, including automatic feeding of aluminum chips, compression, ejection of briquettes, and control of the hydraulic system. This automation streamlines the briquetting process and reduces labor requirements.

Adjustable Pressure: The hydraulic pressure applied during the briquetting process is adjustable, allowing operators to tailor the density and hardness of the briquettes to meet specific requirements or preferences.

Safety Features: Aluminum chips briquetting machines are equipped with safety features to protect operators and prevent accidents. These may include safety guards, emergency stop buttons, and interlock systems to ensure safe operation.

Efficient Design: Features like advanced hydraulic valve systems ensure efficient operation with minimal pressure loss and leakage.

நன்மைகள்:

Waste Reduction: Aluminum chips briquetting machines help reduce waste by compacting loose aluminum chips or shavings into dense, easy-to-handle briquettes. This reduces the volume of waste generated and simplifies storage and transportation.

Cost Savings: Briquetting aluminum chips allows companies to recover the value of the metal and reduce disposal costs associated with waste management. Briquettes can be sold to recycling facilities or metal processing companies for recycling or melting down.

Resource Conservation: Recycling aluminum chips through briquetting helps conserve natural resources by reducing the need for virgin aluminum production. It also saves energy compared to producing aluminum from raw materials, as recycling requires less energy.

Improved Handling: Briquettes produced by aluminum chips briquetting machines are denser and more compact than loose chips, making them easier to handle, store, and transport. This improves efficiency and reduces the risk of accidents or injuries associated with handling loose chips.

Environmental Benefits: Briquetting aluminum chips contributes to environmental sustainability by reducing the environmental impact of aluminum production and waste disposal. It helps minimize greenhouse gas emissions, energy consumption, and landfill usage associated with aluminum waste.

Space optimization: Briquettes are denser than loose chips, allowing for more scrap to be stored in a smaller space.

Increased profitability: Briquettes are a more valuable form of scrap metal compared to loose chips. They are easier to transport and store, leading to reduced handling costs.

Benefits:

Increased Scrap Value: Briquettes are a denser and more manageable form of aluminum scrap compared to loose chips. This translates to a higher selling price per ton for recycled aluminum.

Reduced Storage Space: Briquettes take up significantly less space than loose chips, allowing you to store more scrap in a smaller area, freeing up valuable floor space.

Lower Transportation Costs: Denser briquettes are easier and cheaper to transport due to reduced volume. This translates to significant cost savings, especially for larger operations.

Improved Safety: Loose chips can pose a safety hazard, creating tripping and slipping risks. Briquettes are more stable and easier to handle, minimizing workplace accidents.

Environmental Sustainability: By facilitating efficient aluminum recycling, briquetting machines contribute to a more eco-friendly metal production cycle. They help conserve natural resources and reduce landfill waste.

Recovered Coolant and Oil: The briquetting process can help squeeze out cutting oils and coolants trapped within the chips. These recovered liquids can potentially be reused or disposed of responsibly.

ஒட்டுமொத்த, aluminum chip briquetting machines offer a win-win situation for metalworking businesses.

They not only contribute to a more sustainable industry but also improve profitability through efficient scrap management.

Why us for aluminum chips briquetting machine?

Choosing us for your aluminum chips briquetting machine needs offers several advantages:

Expertise and Experience: We have extensive experience and expertise in the design, manufacture, and operation of aluminum chips briquetting machines. Our team of engineers and technicians understands the unique requirements and challenges of aluminum chip recycling and can provide tailored solutions to meet your specific needs.

High-Quality Equipment: We are committed to delivering high-quality equipment that meets industry standards and exceeds customer expectations. Our aluminum chips briquetting machines are built to last, with robust construction, reliable components, and advanced technology for optimal performance and durability.

Customization Options: We offer a range of customization options to tailor our aluminum chips briquetting machines to your exact requirements. Whether you need a specific capacity, அளவு, or features, we can work with you to design a solution that meets your needs and fits your budget.

Efficient Production: Our aluminum chips briquetting machines are designed for efficiency, productivity, and ease of operation. With features such as automatic feeding, adjustable pressure, and rapid cycle times, our machines help streamline your production process and maximize output.

Cost-Effective Solutions: We understand the importance of cost-effectiveness in your operations. Our aluminum chips briquetting machines are designed to deliver maximum value for your investment, with competitive pricing, low maintenance requirements, and high reliability to minimize downtime and maximize profitability.

Comprehensive Support: From initial consultation to after-sales support, we provide comprehensive assistance every step of the way. Our team is available to answer your questions, provide technical guidance, and offer maintenance and repair services to keep your equipment running smoothly.

Commitment to Sustainability: By investing in our aluminum chips briquetting machines, you are contributing to environmental sustainability by recycling aluminum waste and reducing the need for virgin aluminum production. Our machines help minimize waste, conserve resources, and lower carbon emissions, aligning with your sustainability goals.

ஒட்டுமொத்த, choosing us for your aluminum chips briquetting machine needs ensures that you receive a high-quality, customized solution that delivers efficiency, productivity, and cost-effectiveness for your recycling operations.