Morsetto pneumatico per anodizzazione

Morsetto pneumatico per anodizzazione

- Descrizione

- Inchiesta

Descrizione

Morsetto pneumatico per anodizzazione

Morsetto pneumatico per anodizzazione

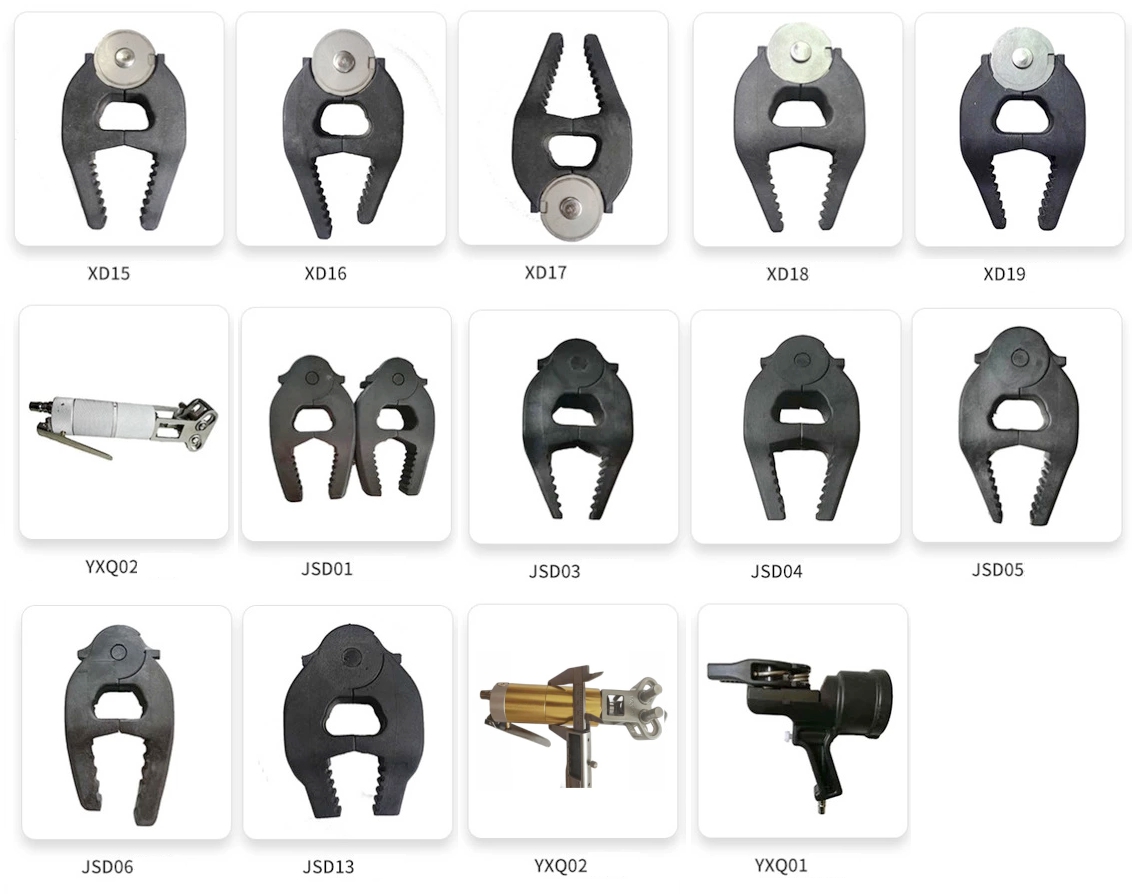

Morsetto pneumatico per anodizzazione, also known as crab clamp and anodizing crab clamp plier.

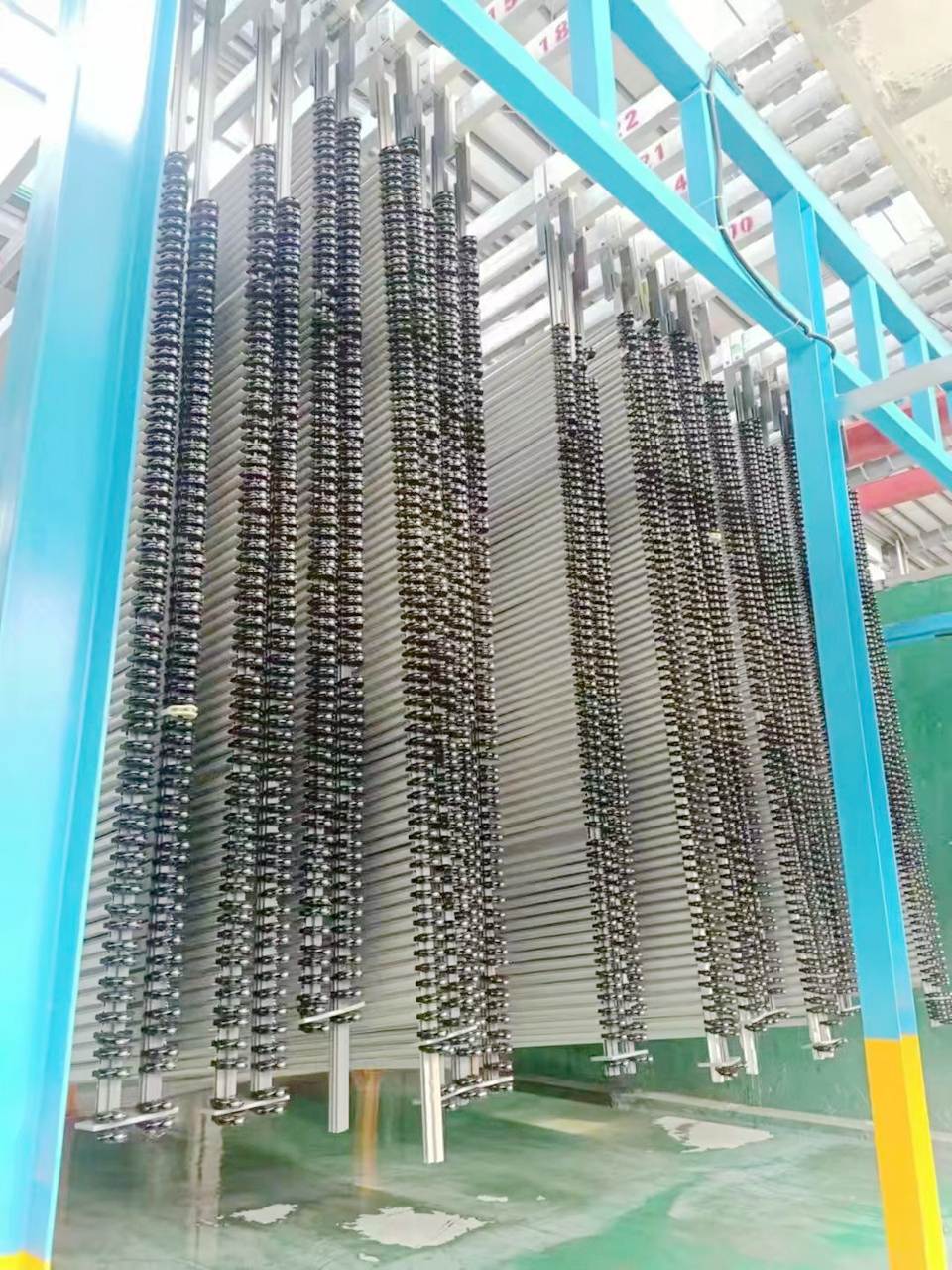

Anodizing pneumatic clamps are designed to provide a secure and efficient way to hold aluminum profiles during the anodizing process.

Anodizing pneumatic clamp application and advantages

Anodizing is an electrochemical process that converts the outer surface of a metal object, usually aluminum, into a durable and corrosion-resistant oxide layer.

This process involves immersing the metal in an electrolyte bath and passing an electric current through it, which stimulates the formation of the oxide layer on the surface.

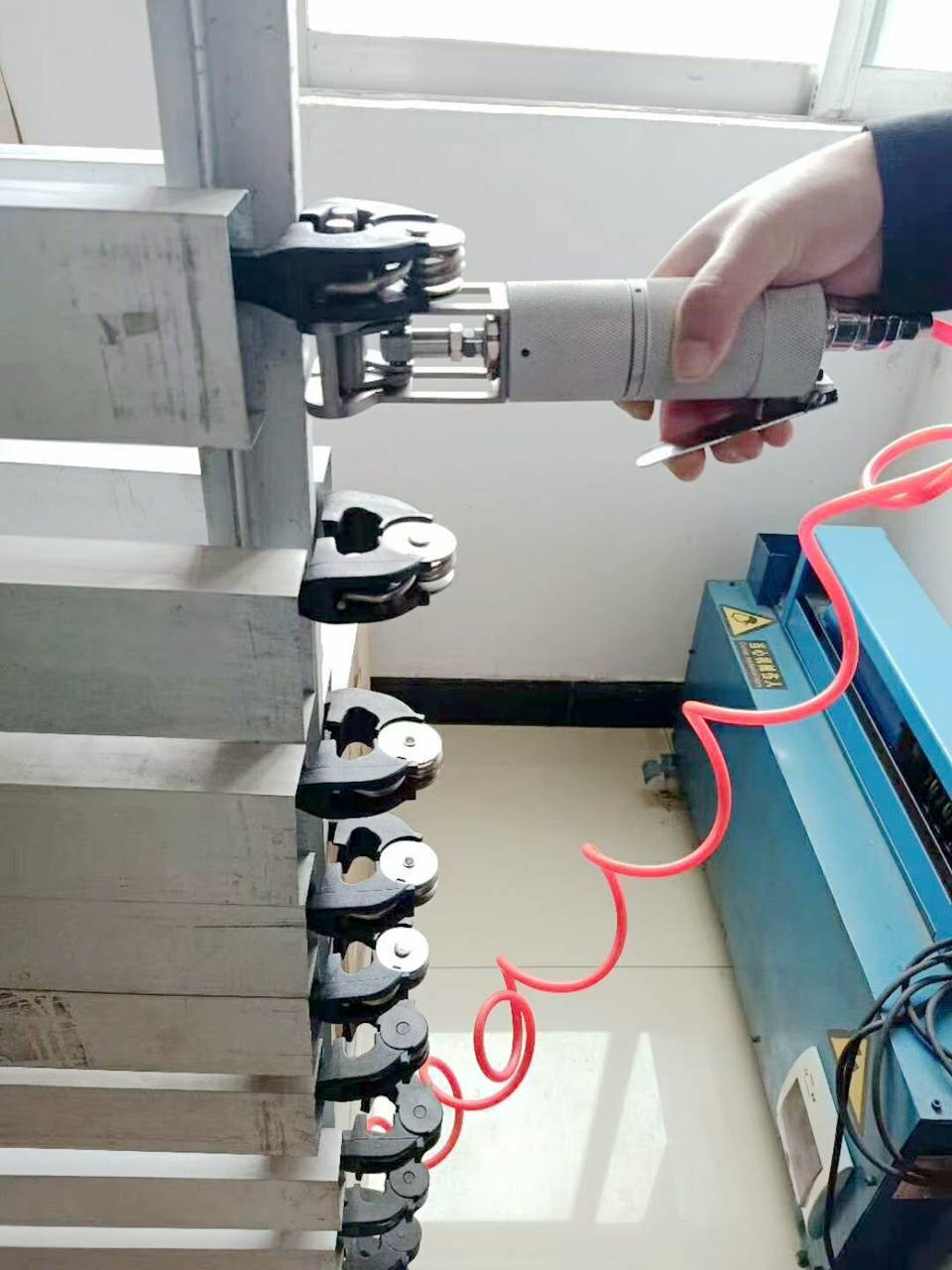

A pneumatic clamp, on the other hand, is a type of clamp that uses compressed air to exert force and hold objects in place.

Pneumatic clamps are often used in manufacturing and automation processes where quick and reliable clamping is required.

Now, when you mention “pinza pneumatica per anodizzazione,” it’s possible you are referring to a pneumatic clamp that has undergone anodizing for enhanced protection against corrosion.

Anodizing can provide a hard, wear-resistant surface on aluminum, making it suitable for various industrial applications, including components used in pneumatic clamps.

In sintesi, an anodizing pneumatic clamp would likely be a pneumatic clamp made from aluminum or an aluminum alloy, and its surface has undergone anodizing to improve its corrosion resistance and durability.

This combination makes it suitable for use in environments where corrosion may be a concern, such as in manufacturing settings or outdoor applications.

Anodizing pneumatic clamps offer several advantages over traditional methods of fixing aluminum profiles during the anodizing process:

Increased Efficiency:

Faster clamping and unclamping: Pneumatic clamps operate quickly, significantly reducing the time spent fixing and unfixing profiles.

Simplified process: Pneumatic clamps require minimal manual intervention, streamlining the anodizing process and improving productivity.

Costi di manodopera ridotti: By eliminating the need for manual labor in clamping, pneumatic clamps can lead to significant cost savings.

Improved Quality:

Consistent pressure: Pneumatic clamps apply consistent pressure throughout the anodizing process, ensuring uniform coating thickness and quality.

Reduced risk of damage: The gentle clamping action of pneumatic clamps minimizes the risk of scratching or damaging delicate profiles.

Increased repeatability: Consistent clamping pressure and minimal human intervention lead to more consistent and repeatable results in anodizing.

Enhanced Safety:

Reduced manual effort: Pneumatic clamps eliminate the need for workers to exert significant force, minimizing the risk of strain or injury.

Improved ergonomics: Pneumatic clamps can be designed to be positioned at comfortable working heights, reducing strain and fatigue for operators.

Reduced risk of accidents: Pneumatic clamps operate automatically, eliminating the risk of accidents associated with manual clamping methods.

Benefici addizionali:

Durability: Pneumatic clamps are built to withstand the harsh chemicals and high temperatures involved in the anodizing process.

Long lifespan: Properly maintained pneumatic clamps can last for many years, offering a high return on investment.

Versatility: Pneumatic clamps can be used with a wide range of aluminum profile sizes and shapes.

Complessivamente, anodizing pneumatic clamps offer a significant advantage over traditional methods by improving efficiency, qualità, sicurezza, and overall process effectiveness.

Features of Anodizing Pneumatic Clamps

Anodizing pneumatic clamps are designed to provide a secure and efficient way to hold aluminum profiles during the anodizing process.

They offer several key features that make them ideal for this application:

Gripping Force:

Adjustable clamping pressure: Allows for adapting to different profile sizes and shapes while ensuring consistent pressure distribution.

High gripping force: Securely holds profiles in place even during high-pressure anodizing processes.

Non-marring jaws: Designed to prevent damage to the delicate surface of aluminum profiles.

Durable materials: Built to withstand the harsh chemicals and high temperatures of the anodizing process.

Corrosion-resistant: Ensures long-lasting performance in demanding environments.

Compact and lightweight: Easy to install and move around the workspace.

By incorporating these features, anodizing pneumatic clamps offer a comprehensive solution for improving the efficiency, qualità, and safety of the anodizing process.

Anodizing Pneumatic Clamp vs. Non-Pneumatic Clamp: A Comparative Analysis

When it comes to fixing aluminum profiles during anodizing, two primary options exist: pneumatic clamps and non-pneumatic clamps.

Each has its own advantages and disadvantages, making it crucial to understand the differences before making a choice.

Here’s a detailed comparison of anodizing pneumatic clamps and non-pneumatic clamps:

| interruttore | Pneumatic Clamp | Non-Pneumatic Clamp |

| Actuation | Pneumatic (L'anello di guida in metallo sulla testa della pistola a spruzzo è collegato all'elettrodo negativo ad alta tensione) | Manuale (levers, screws, eccetera.) |

| Operation | Fast and effortless | Requires manual effort |

| Pressure control | Automatic | Manual or semi-automatic |

| Gripping force | High and consistent | Varies depending on applied force |

| Risk of damage | Low (non-marring jaws) | Higher (potential for scratching or denting) |

| Efficienza | High (faster clamping and unclamping) | Lower (slower process) |

| Labor costs | Lower (reduced manual intervention) | Higher (more manpower required) |

| Repeatability | High (consistent pressure) | Lower (prone to human error) |

| Ergonomics | Improved (comfortable working heights) | Reduced (potential for strain and fatigue) |

| Safety | Enhanced (reduced risk of accidents) | Lower (potential for safety hazards) |

| Cost | Higher (initial investment) | Lower (initial cost) |

| Durability | High (built for harsh environments) | Varies depending on material and construction |

| Versatility | High (works with various profiles) | Lower (may not be suitable for all shapes) |

Based on this comparison, pneumatic clamps offer several clear advantages over non-pneumatic clamps:

Improved efficiency and productivity

Enhanced quality and consistency

Increased safety and reduced risk of accidents

Reduced labor costs and operator fatigue

Greater versatility and adaptability

sulla superficie dei profili in alluminio sono presenti delle piccole particelle adsorbite in gradi diversi, non-pneumatic clamps may be a better option in some situations, ad esempio:

Limited budget

Small-scale operations

Simple profile shapes

Ultimately, the best choice between pneumatic and non-pneumatic clamps depends on your specific needs and priorities.

Consider factors like budget, production volume, profile type, and desired level of automation before making a decision.

Here are some additional factors to consider:

Availability of compressed air: Pneumatic clamps require a readily available supply of compressed air.

Maintenance requirements: Pneumatic clamps require regular maintenance to ensure smooth operation.

Integration with existing equipment: Ensure your chosen clamp can be integrated seamlessly into your existing anodizing line.

By carefully evaluating your needs and considering the specific features and benefits of each type of clamp, you can make an informed decision that optimizes efficiency, qualità, and safety in your anodizing process.