Aluminium dross recovery system

Aluminium dross recovery system

- Description

- Inquiry

Description

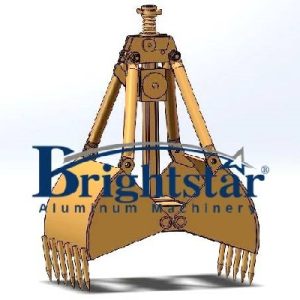

Aluminium dross recovery system

Aluminium dross recovery system

All in one aluminium dross processing system

Aluminium dross recovery system: Aluminium dross machine processes hot dross generated from melting furnace and holding furnace, aluminium dross processing system, ball mill sieving aluminium dross cooling machine main function is to cool the hot dross generated from rotary furnace or dross processing machine through water spraying, break up, ball mill grind and crush, separate in different grades so that it can get improving aluminium recovery rate purpose.

Our company makes improvements and innovations for the dross processing and cooling system based on the customers’ feedback and consideration of the equipment’s own features.

Dross processing, cooling/breaking up, ball mill grinding, sieving and separating, four processes in one; Aluminium dross will be sent to the dross cooling machine directly, no need any transit; Consideration for both fine and coarse dross separating; Aluminium dross cooling drum is water spraying cooling.

Aluminium dross recovery system description

The first step, extract aluminium from the hot dross generated from aluminium melting furnace or holding furnace, more than 90% recovery rate

The second step, cool the hot dross(700-900℃) after the processing to normal temperature within 10-15 minutes, avoid burning loss and oxidation, improve the recovery rate

The third step, crushing and grinding in the ball mill

In the fourth step, sieving in different grades, coarse dross will be recycled in the melting furnace, medium dross will be used in the dross processing machine for dross cooling, and fine dross will be bagged for sale.

All-in-one aluminium dross processing system is the matched cooling, grinding and screening equipment for the aluminium dross machine and rotary furnace.

The main function is to cool down the hot dross after aluminium dross processing or rotary furnace through water spraying and heat exchange.

The purpose of cooling and screening in grades can reduce the burning loss of aluminum during the aluminium dross cooling process, effectively improving the recovery rate of aluminium.

The dross cooling, ball mill and screening machine are divided into a cooling rotary drum and screening drum, each has an independent transmission system, the cooling drum rotation speed is 2 rpm, the screening drum speed is 0-25 rpm, there are 3 discharge ports for the dross, which are fine, medium and coarse dross.

The cooling method of aluminium dross cooling machine is circulating water spraying, and the equipment base is a circulating cooling water pool.

The cooling water is evenly covered with the cooling drum body through the water pump and the spraying water pipe, and the hot aluminium dross exchanges heat with the cooling water through the drum body.

The cooling water temperature should not exceed 40°C to ensure the cooling effect of the hot aluminium dross.

If the amount of hot aluminium dross to be treated is too large, external circulating water can also be considered.

The hot aluminium dross from aluminium dross machine will be flowed to aluminium dross cooling drum, which is connected together and it is automatic operation.

If the hot aluminium dross is from the rotary furnace, which is poured into the dross hopper and sent to the charging port of the dross cooling drum with a forklift.

It is cooled rapidly by spraying the cooling water outside the cooling drum. After cooling, it goes into the ball milling area at the back end of the dross cooling drum.

Grind the coarse dross and block dross into fine pieces, grind the fine-grained aluminum beads flat, and then pass through the screening area to sieve out the 60-mesh fine dross (aluminum content < 3%), and then sort out the medium particles below φ12mm (aluminum content about 15-25%) and coarse particles above φ12mm (aluminum content about 10-15%),

If there is more iron in the aluminum dross, a magnetic separator can be installed at the coarse particle dross unloading port to sort out the iron scraps.

The fine, medium and coarse aluminium dross screened out by 3 in 1 aluminium dross processing system can be processed according to the needs.

The fine aluminium dross does not contain high aluminum content and can be directly sold out.

The medium aluminium dross and the coarse aluminium dross after iron removal can be sent back into the rotary furnace or melting furnace, both as a cooling agent and secondary aluminium recovery, as there is aluminum metal in medium and coarse dross.

The supporting cycle operation with the rotary furnace can increase the recovery rate of aluminum dross, and the economic benefits and social benefits are very obvious.

Technical features of aluminium dross recovery system

Automatic and save the labor, simple operation and less maintenance;

Improve aluminium recovery rate, avoid the burning loss and oxidation;

Minimize the smoke and dust problem, good for the workers’ health and meet the government ‘ request for the environment friendly;

Long time running without failure, high efficiency and energy saving;

Better economic benefits and social benefits and environmental benefits with our system.

Technical data of aluminium dross recovery system

Overall size 10-17 meters up to project

Total power: 40-50 KW

Water consumption for cooling 10-30m3/H

Processing quantity: 1-3 tons per hour up to the project

We will design, manufacture based on your production situation and from design, manufacturing, and delivery to installation, commissioning, training, technical support and service, one-stop service and we do more than you expected.

Contact us now to obtain a reliable no-obligation quote on your hot aluminium dross recovery solution.