உருகும்போது ஆக்சிஜனேற்றம் எரியும் இழப்பை எவ்வாறு குறைப்பது

உருகும்போது ஆக்சிஜனேற்றம் எரியும் இழப்பை எவ்வாறு குறைப்பது

உருகும்போது ஆக்சிஜனேற்றம் எரியும் இழப்பை எவ்வாறு குறைப்பது

The method that reduces oxidation loss in the melting

உருகும்போது ஆக்சிஜனேற்றம் எரியும் இழப்பை எவ்வாறு குறைப்பது, Oxidation loss is inevitable in aluminium melting, we can take some measures to reduce oxidation loss, so that we can improve the metal yield rate and metal quality.

Here are the measures for the reduction of melting oxidation burning loss

1. Get reasonable furnace shape

Make the molten pool area as small as possible, speed up heating time, போன்றவை, increase heating strength or use oxygen enrichment for reverberatory, electric furnace adopts high power transmission, or use electrical electromagnetic inductor for the stirring in the bottom of melting furnace, all can shorten the melting time, reduce oxidation loss.

For ASARCO shaft kiln melting furnace, use natural gas or LPG as fuel, high heat efficiency and can be in sustained production. Adopting a round flame furnace and top fast charging technology aluminum melting furnace, can shorten charging time and melting time, reduce energy consumption and oxidation loss.

2. Control the furnace temperature reasonably

In the condition of keeping the metal melts flowability and refining process requirement, the temperature can not be too high.

Before furnace charging melting, we need to make high-temperature quick heating and melting, after it, we need to regulate the control the furnace temperature, don’t make the melts too hot.

3. Control the furnace gas properly

When melt aluminium and aluminium alloy that is easy oxidized and hydrogen pickup, should choose micro oxidation gas.

4. Charging and operating properly

Put the furnace charging that is easily oxidized into the bottom layer in the furnace, or put it later after the other furnace charging melted, or put them in as master alloy.

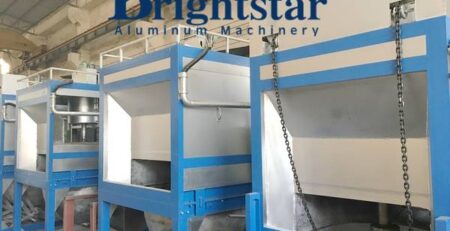

Chipping scraps should be remelted or pressed high-density material bag for melting, avoid frequent stirring to keep the oxidation film full, அல்லது double chamber aluminium chips melting furnace with side well vortex stirring system can be applied for chips melting.

5 Use covering agent and surface active element

Drop flux in the surface of furnace charge, which can reduce oxidation loss.

Especially chipping scraps will be covered with the flux for the melting and refining, or can add a little α >1 surface active element to improve melts surface oxidation film property, which can reduce burning loss in the melting.

Here are the measures to reduce oxidation burning loss in the melting.