Puț de turnătorie de curățare a zgurii de aluminiu

Puț de turnătorie de curățare a zgurii de aluminiu

- Mașină automată de degazare a rafinarii aluminiului topit

- Mașină automată de degazare a rafinarii aluminiului topit

Mașină automată de degazare a rafinarii aluminiului topit

Puț de turnătorie de curățare a zgurii de aluminiu

Puț de turnătorie de curățare a zgurii de aluminiu

Foundry well cleaning magic weapon

Energy saving, ECO, Safe and High efficiency

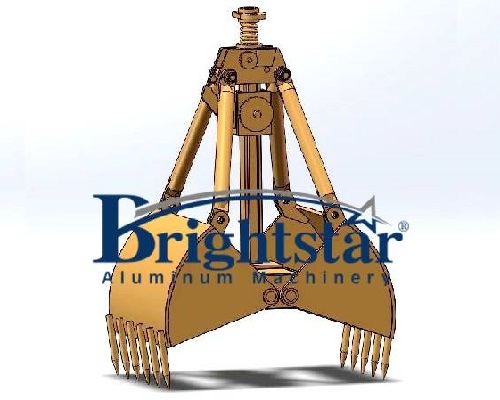

Foundry well aluminum slag cleaning grab bucket is specially designed for aluminum casting workshop, which can replace manual deep casting well operation, and improve work efficiency.

It is used to clean and recover the aluminum slag at the bottom of the aluminum billets casting well, without pumping water or manually going down the well to clean it.

The aluminum slag cleaning grab bucket is suitable for all kinds of cranes with only one lifting reel (single hook).

Its opening and closing mechanism is creative, and it can be opened and closed freely when loading and unloading materials.

Save labor and effectively protect the safety of staff.

The use of a single-rope grab bucket can completely replace the status of manual slag removal in deep wells (wire rope casting), and avoid safety accidents when people work in a limited space such as deep wells

(1. Workers are killed or injured by falling objects; 2. Harmful gases lead to personnel poisoning or hypoxia, etc.).

conținutul de hidrogen al lichidului de aluminiu trebuie menținut la un nivel scăzut, it can greatly save manpower and material resources.

(It usually takes 5 people at least 2 days to clear aluminum slag of a deep well, now, with the well cleaning magic weapon, it only takes 2 people and half a day to clear aluminum slag of a deep well).

Parametrul tehnic principal

1. Lifting weight: 2.8T

2. Bucket capacity: 0.75 m³

3. Volume weight: ≤1.2 T/m³

4. Pulley diameter: φ200 mm

5. The ratio of pulley block: 3

6. Wire rope diameter: φ16 mm

Working Principle:

The opening and closing of the single-rope grab bucket is mainly due to the coordinated movement of elastic elements, carriages, and lock hooks.

When grabbing materials, after the opened grab bucket falls on the material, the steel wire rope continues to descend to make the carriage slide down.

Due to the action of the spring on the carriage, the grab opening is on the hook, and the operator lifts the carriage to raise the lower beam, so the Jaws plate will be closed.

When unloading, when the full load is sent to the pile or the ground of the unloading site, the steel wire rope continues to descend, causing the carriage to slide down for a certain distance, and the pressure on the claws from the hook mouth immediately loses.

Under the action of the pressure spring on the head, the gripper rotates and disengages from the hook opening, and the operator rises up again, and the jaws are gradually opened under the action of the lower crossbeam and the self-weight of the material.

Operation steps:

1. Check whether the operating parts are flexible.

2. The operator starts the hoist or crane, and the opened grab bucket falls to the material.

3. The steel wire rope slides down to hook the pallet and rises at a constant speed.

4. When unloading, the steel wire rope slides down for a certain distance, releases the clamping plate, and then lifts up.