Reciclagem de sucata de alumínio

Reciclagem de sucata de alumínio

Reciclagem de sucata de alumínio

Reciclagem de sucata de alumínio, today recycled aluminium accounts for one-third of global aluminium consumption in Europe and aluminium recycling is a well-established industry.

Recycling aluminium can require only as little as 5% of the energy needed to produce the primary aluminium from bauxite.

Any aluminium product can be recycled and the metal can be melted again indefinitely.

There is no difference between primary and recycled aluminium in terms of quality or properties.

This explains why the value of aluminium scrap is relatively high compared to the price of aluminium ingots.

There are two categories of aluminium destined for recycling: new and old scrap.

New scrap

New scrap is surplus material that arises during the manufacture and fabrication of aluminium alloy within the aluminium and manufacturing industry.

This scrap is usually of known quality and composition and can therefore be melted down with little preparation.

Examples include the trimmings from the edges of sheet aluminium, turnings and millings from aluminium fabrication and aluminium extrusion scraps.

Nearly 100% of all new scrap is recycled.

Old scrap originates from the end-of-life of final products. Such scrap could be beverage cans, car cylinder heads, window frames from demolished buildings or old electrical cabling. This scrap is recycled on average at 70-80% mainly into casting alloys and to a lesser extent into wrought alloys depending on quality and specifications.

Old scrap

Old scrap is sorted at a recycling plant to determine composition and value.

Sorting of aluminium is a key factor for optimum recycling: eddy current machines (ECM), detector ejectors, heavy media separation have been developed to extract aluminium from mixed waste streams and work is underway on automatic sorting of aluminium alloys by main categories.

The scrap is then prepared before the melting process in order to remove the major non-aluminium components (e.g. coatings of used beverage containers UBC).

Other impurities are collected in the aluminium dross of the metal bath.

These drosses are processed again to recover the aluminium, and the secondary dross is disposed of in controlled conditions.

The scrap aluminium is completely melted in a furnace and this molten metal is then cast or processed using the same techniques as primary processing.

New scrap and old scrap recycling

New scrap is mainly recycled by remelting, which are generally integrated into rolling mills and aluminium extrusion plants.

Secondary refiners melt a mix of different scrap grades (mostly old scrap) to produce casting alloys to targeted specifications.

Most of the old scrap is recycled in an “open-loop” (ou seja. not exactly into the same alloy composition), because many scrap lots are mixed and because the demand per alloy evolves differently for each alloy.

There are two major “closed-loop” (ou seja. into exactly the same alloy) old scrap recycling routes:

The ‘carter’ grade (for engine blocks)

The Used Beverage Containers (UBC) recycling to produce new can stock

UBC Recycling

Schematic flow chart

Melting furnace←Decoater←Vibrating fines screen←Magnetic Separator←Shredder←UBC feed

↓

Tilting holding furnace→Degassing filtration unit→Direct chill casting unit→Canstock slabs

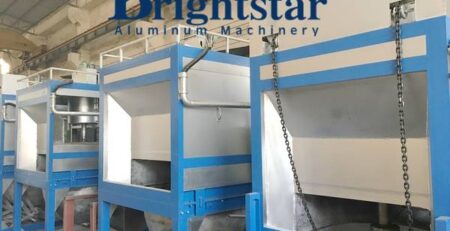

Brightstar Aluminum Machinery offers aluminium scrap rotary kiln, aluminium dross recovery machine and aluminium dross cooling machine for primary and secondary aluminium production.

Contact us now to obtain reliable No-obligation quotes.