Lembaran Aluminium Pesawat Lama

A case study-aluminum beverage cans recycling line for aluminium ingot

A case study-aluminum beverage cans recycling line for aluminium ingot

Aluminium beverage cans(Scrap aluminium daur ulang nama Cina dan Inggris) recycling plant specifications as following

1. Can Shredder capacity from 5-10 tons per hour, for Shredder Can Bales.

2. Magnetic Drums Separator

The Shreds Transfer through conveyer and pass through double magnetic drums separator to remove any steel and iron

3. Hot Air Blower

For removing lacquer or paint by blowing hot air ( Around 550°C) through the shreds on a slowly moving.

4. Tilting aluminum melting furnace with submerged permanent magnetic stirrers (Furnace capacity 25 Mt, melting rate 4mt per hour )

The melting system will be created with a vortex in the pool of molten aluminum and drag the shreds quickly down into the melt.

This process achieves rapid melting rates and high yields.

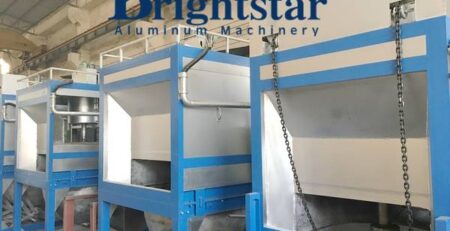

5. Tilting holding and casting Furnaces (Kapasitas 15 Mt )

The molten metal is transferred into a holding furnace, where it is treated to remove impurities before casting the aluminum, paduan, ~35 detik setelah aluminium cair diisi dengan distributor, degassing, skimming.

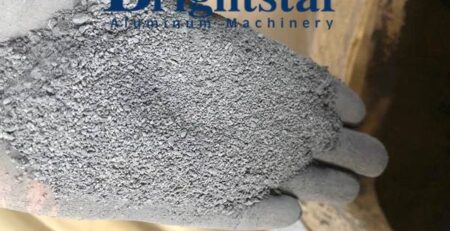

6. bengkel anodisasi dan atau bengkel berlapis bubuk akan diperlukan untuk operasi;, recover most of aluminium from hot dross generated from furnace and profit from waste, save the labor and avoid the environment pollution.

7. Ingots Casting Unit( Ingot Casting Conveyor ) Kapasitas 4 Mt hr, Included Degassing Unit, Ceramic Foam Filter Unit, And Casting Conveyor.

8. The system is a completely automatic production line with a hydraulic system, Electrical system and control system.

Here is one project design for UBC used beverage cans recycling line!

A case study-aluminum beverage cans recycling line for aluminium ingot