Aluminum dross has been classified as hazardous waste! treatment method must be changed

Aluminum dross has been classified as hazardous waste! treatment method must be changed

Aluminum dross has been classified as hazardous waste! treatment method must be changed

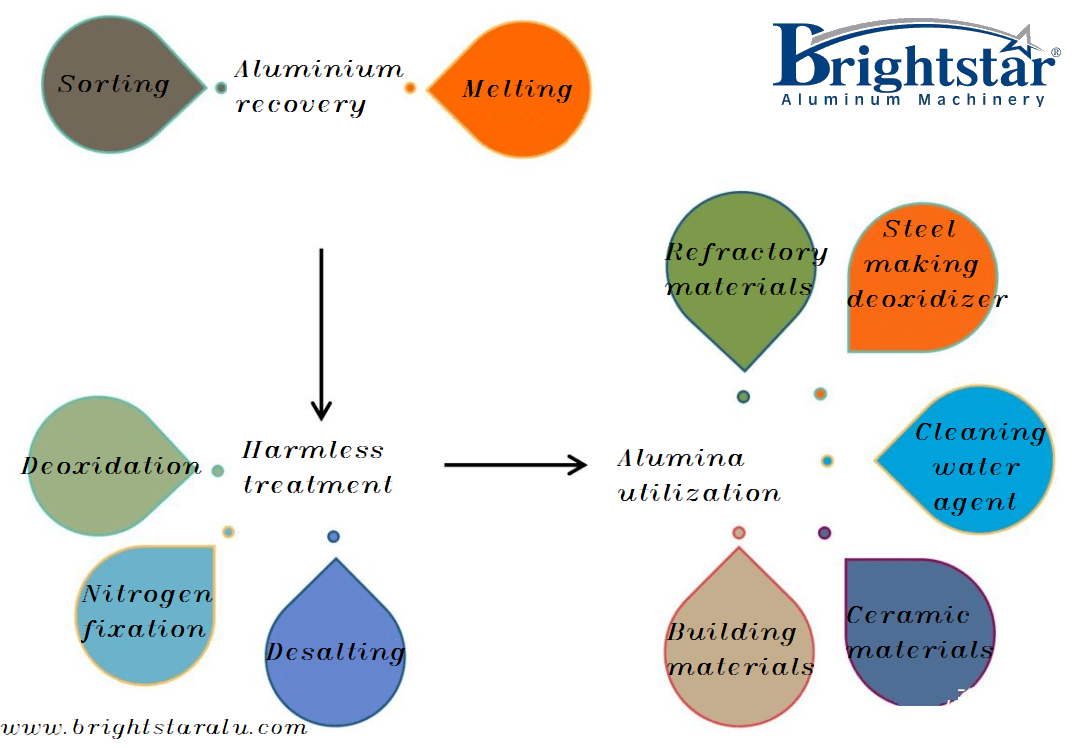

Aluminum dross has been classified as hazardous waste, the processing method must be changed, the processing of aluminum dross hazardous waste can be harmless and recycling processing.

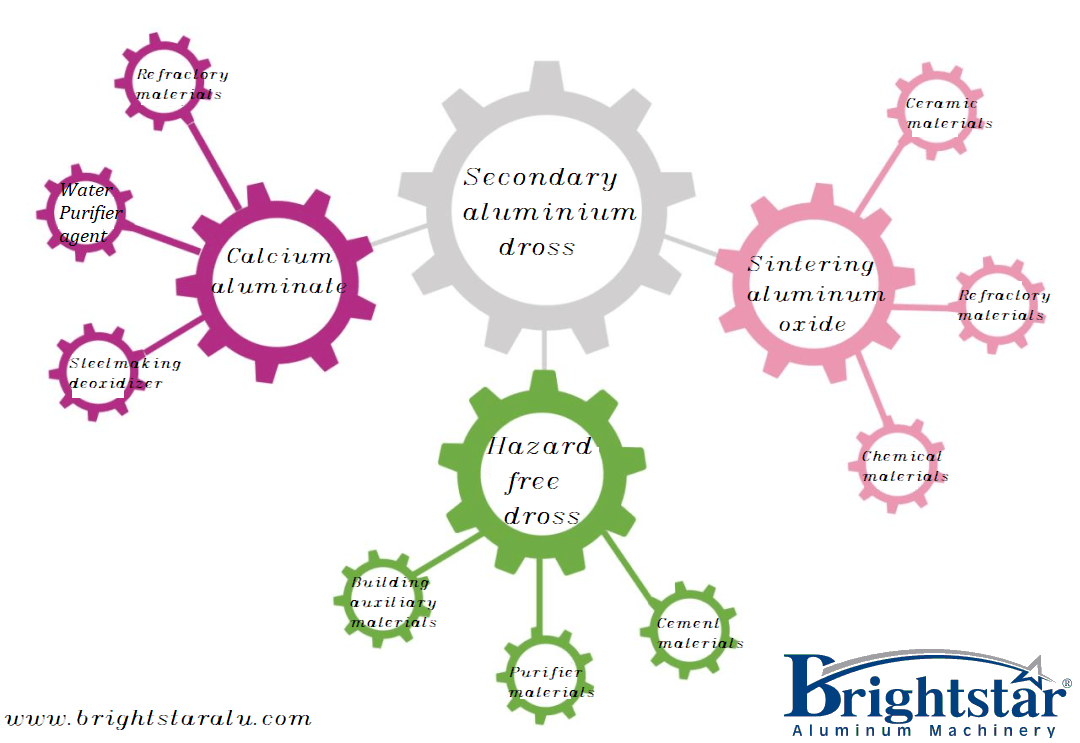

Harmless process: through acid leaching, alkaline leaching, washing, etc., the nitride, fluoride, salt and other impurities in the secondary aluminum dross are removed to obtain harmless aluminum dross, which is then safely landfilled.

Recycling process: After removing toxic and harmful substances, the secondary aluminum dross is processed into different products through high temperature or cold processing, such as steel claw guard ring, brown corundum abrasive, refining agent and water purifying agent, etc., or it is returned to the electrolytic cell for electrolysis aluminum raw materials.

Secondary aluminum dross is a kind of hazardous waste, which contains a lot of toxic and harmful substances such as fluoride, cyanide, aluminum carbide, aluminum nitride and so on.

At present, it has been included in the “National Hazardous Waste List”, the waste category is HW48 non-ferrous metal smelting, and the waste code is 321-224-48.

Because AlN, Al4C3 meet water to produce NH3 and CH4 and other gases, their odor, fluoride and cyanide dissolved in water will pollute the natural water body, so if it is directly landfilled without treatment, it will cause environmental damage serious harm.

1. What are the harmful elements of aluminum dross

1.1. Nitrogen (N): mainly exists in the form of AlN, and ammonia gas will be produced when it meets water;

(AlN+H2O=Al2O3+NH3↑)

1.2. Fluorine (F-): mainly exists as fluoride, and releases fluoride ions when it meets with water;

Na3AlF6, Na2SiF6, AlF3, NaF, MgF2

1.3. Chlorine (Cl): mainly exists as chloride salt, which is harmful to the product, corrosion to equipment;

Zinc (Zn) Lead (Pb) Arsenic (As) Mercury (Hg) Copper (Cu) Chromium (Cr)

2. Classification of aluminum dross

2.1. From the source, it can be divided into electrolytic aluminum dross and recycled aluminum dross;

2.1.1. The floating dross produced in the process of aluminum electrolysis is called electrolytic aluminum dross. 1 ton of electrolytic aluminum can produce about 10-15 kilograms of aluminum dross.

2.1.2 The floating dross generated during the recycling and remelting of scrap aluminum is called recycled aluminum dross, and 100 to 200 kilograms of recycled aluminum dross will be produced during the entire process of aluminum processing and application per ton.

2.2. From the process, it can be divided into primary aluminum dross and secondary aluminum dross;

2.2.1. The aluminum dross produced in the process of electrolytic aluminum production, secondary aluminum production, and aluminum ingot casting, the content of metallic aluminum is about 20% to 60%;

2.2.2. The fine dross after the metal is separated from the aluminum dross, the content of metallic aluminum will be about 5%-10%.

3. About the utilization and disposal of solid waste

3.1. The solid waste generated in the secondary aluminum industry shall be utilized and disposed of in accordance with the principle of “reduction, resource utilization, and harmlessness”.

3.2. Secondary aluminum enterprises should be equipped with heat treatment equipment to encourage qualified enterprises to utilize resources in the factory.

3.3. The pollutants of dust collected by the bag dust removal device during the smelting process should be handed over to a qualified enterprise for treatment.

4. Judgment rules after mixing (disposal) of hazardous waste

4.1. Hazardous wastes with one or more hazardous characteristics such as toxicity and infectivity are moderated (disposed) with other solid wastes, and the mixed (disposed) wastes are classified as hazardous wastes.

4.2. Hazardous wastes that are only corrosive, flammable or reactive are mixed with other solid wastes (disposal), and the mixed (disposed) wastes are not classified as hazardous wastes if they are identified as not having hazardous characteristics.

4.3. Hazardous waste and radioactive waste are mixed, and the mixed waste shall be managed in accordance with radioactive waste.

5. Technology for comprehensive utilization of aluminum dross

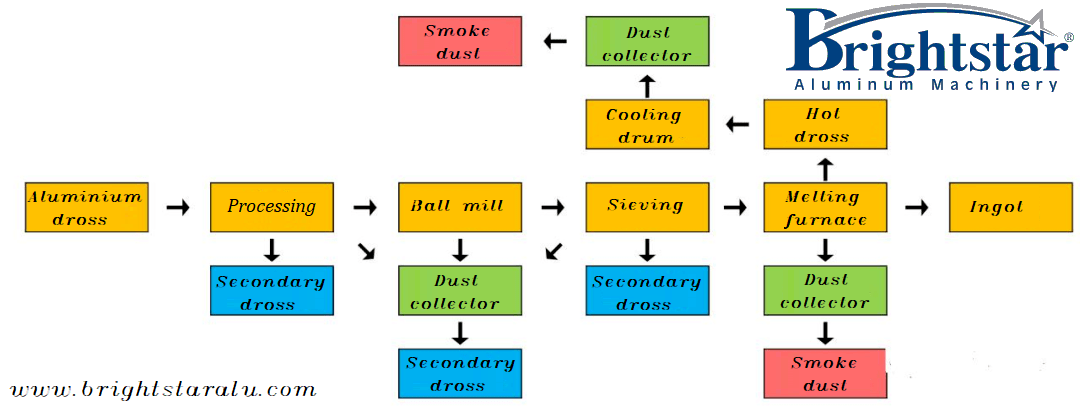

Aluminum dross undergoes industrial treatments to extract valuable products, including metallic aluminum.

Basically, three methods of aluminium dross treatment are used:

Pyrometallurgical, which is a conventional method of treating aluminium dross, liberating metallic aluminum in the liquid state.

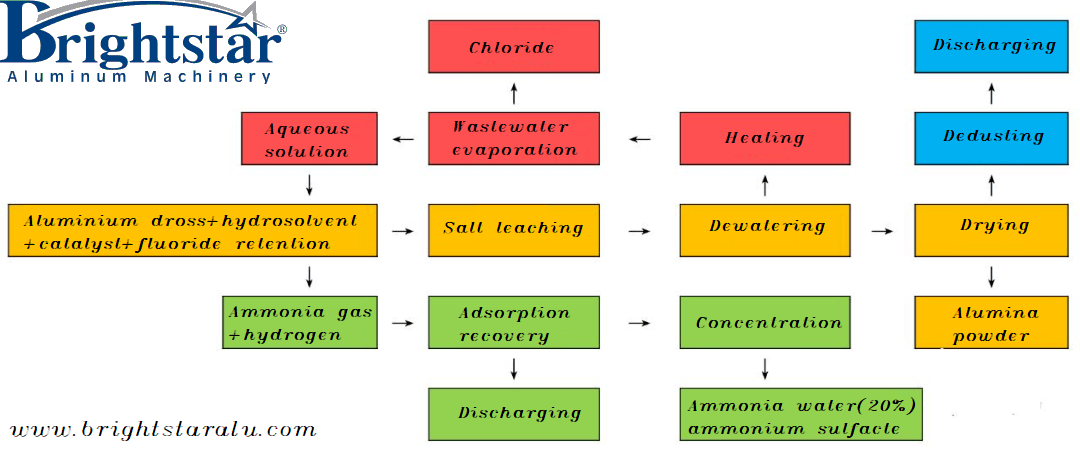

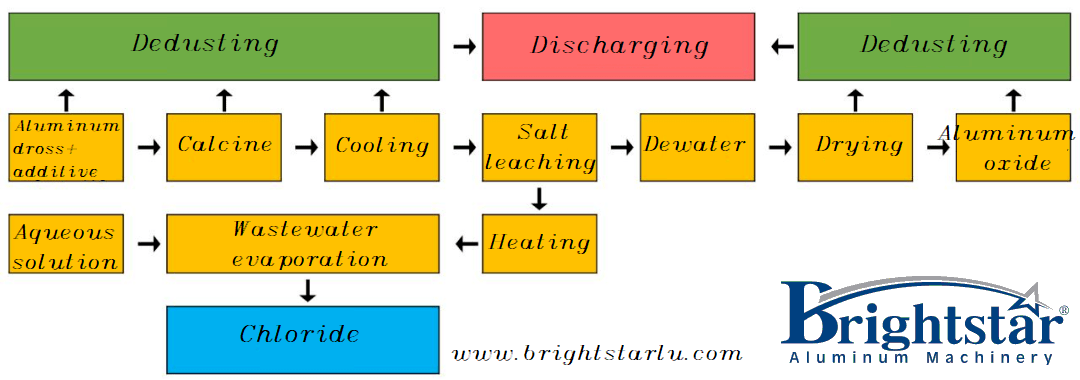

Hydrometallurgical, which involves extraction of metallic aluminum from aluminium dross by converting it into aluminum salts and compounds.

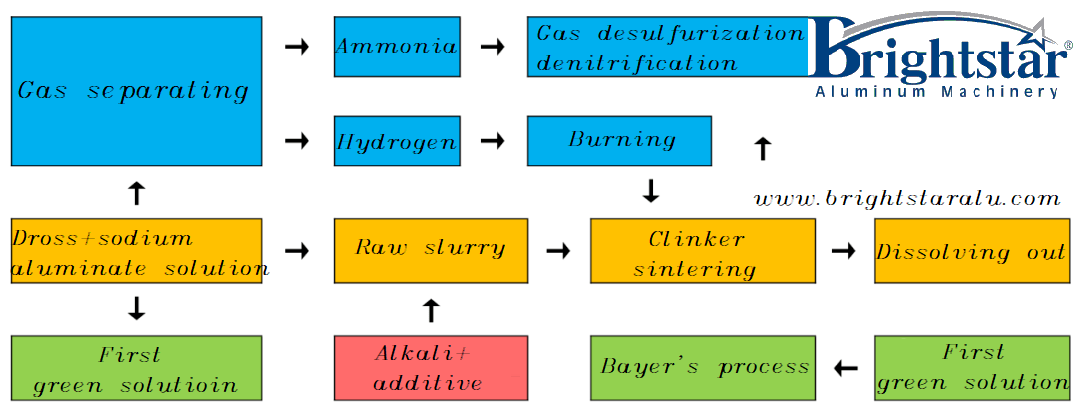

Bayer process, the Bayer process is to treat bauxite with a circulating mother liquor containing a large amount of free caustic alkali, dissolve the alumina in it to obtain a sodium aluminate solution, add aluminum hydroxide seed crystals to the sodium aluminate solution, and then precipitate after a certain period of stirring and decomposition.

Aluminum hydroxide, the decomposition mother liquor is evaporated and used to dissolve the next batch of bauxite.Bayer process” is a method invented by the Austrian chemist K•J•Bayer in 1887 to process high-quality bauxite to produce alumina.

5.1 Aluminum metal recovery

5.2 Harmless processing

5.2.1 Hydrometallurgical, pyrometallurgical and Bayer process

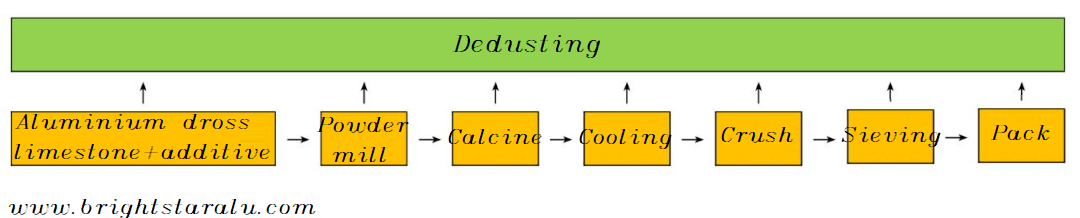

5.2.2 Pyrometallurgical process( calcium aluminate production)

5.2.3 Pyrometallurgical and Hydrometallurgical process(Production of sintering aluminium oxide)

5.2.4 Hydrometallurgical, pyrometallurgical and Bayer process

5.3 Non-toxic process

Brightstar Aluminum Machinery provides aluminium dross machine, dross cooling machine, ball mill and sieving machine and integrated automatic aluminium dross processing system for our customers.

Total solution and one package deal! Turnkey project and one stop service!